Designed for all conditions, our 3 and 5 HP single stage compressors are perfect for just about everyone, from people who excel at DIY projects to professional air compressor users. When performance is determined by maximum operating pressure.

Increased airflow and extended duty cycles, Ingersoll Rand is your best bet. You'll get a compressor that features maximum air capacity, reliable precision-manufactured components, and a rugged design built to last.

Durability:Rugged cast iron construction, extended pump life rated for over 5,000 hours of uptime

Maximum power and flexibility: 100% continuous duty, high pressure operation up to 135 psi. Inch and 60 gallon ASME vertical receiver provide excellent performance for the most demanding applications.

Ease of operation: Start/stop pressure switch automatic control, fully assembled and pre-assembled delivery, easy to replace filter, oil level gauge and easy to fill oil port simplify operation and maintenance

Advanced safety features: Manual thermal motor overload protection and fully enclosed belt guard provide continuous protection

Reliable performance All Season Select synthetic lubricant improves efficiency; with 2,000 hours of service between changes, it lasts four times longer than petroleum-based lubricants

Two-Year Warranty Available: Purchase the Select All-Season Lubricant Starter Kit and get all parts needed for start-up and first year of service, plus an extended pump warranty.

Designed for compactness, economy and reliability, our vacuum pumps are the number one choice for demanding applications, delivering maximum performance combined with minimum maintenance costs.

And best of all, these vacuum pumps are backed by Ingersoll Rand, the world's leading manufacturer of air compressors and pumps.

Durability:Sturdy cast iron frame and cylinder design

Superior pump efficiency: individually cast cylinders with deep radial fins for improved cooling and efficiency

Ease of Maintenance: Accessible stainless steel valve and one-piece connecting rod simplify maintenance and repair

Advanced safety features: standard low oil level switch to provide continuous compressor protection

Reliable performance: All Season Select synthetic lubricant improves efficiency; with 2,000 hours of service between changes, it lasts four times longer than a petroleum-based lubricant

Two-Year Warranty Available: Purchase the Select All-Season Lubricant Starter Kit and get all parts needed for start-up and first year of service, plus an extended pump warranty.

Ingersoll Rand Type 30 Series High Pressure Air Compressors feature base mounted piston technology that delivers pressures up to 5,000 psi (345 barg). Typical applications include gas stations, PBMs, power stations and engine starting. Using the same rugged design as all of our two stage reciprocating compressors, high pressure units provide reliability, long life and easy maintenance.

Durability: Rugged cast iron frame and cylinder, rugged steel base, NEMA compliant motor housing

Superior pump efficiency: individually cast cylinders with deep radial fins for improved cooling and efficiency

Soft start: automatic start/stop regulation by pressure switch centrifugal unloader provides no-load start for maximum protection

Advanced safety features: standard low oil level switch to provide continuous compressor protection

Reliable performance: All Season Select synthetic lubricant improves efficiency; with 2,000 hours of service between changes, it lasts four times longer than a petroleum-based lubricant

Two-Year Warranty Available: Purchase the Select All-Season Lubricant Starter Kit and get all parts needed for start-up and first year of service, plus an extended pump warranty.

Ingersoll Rand Type 30 Series High Pressure Air Compressors feature base mounted piston technology that delivers pressures up to 5,000 psi (345 barg). Typical applications include gas stations, PBMs, power stations and engine starting. Using the same rugged design as all of our two stage reciprocating compressors, high pressure units provide reliability, long life and easy maintenance.

Durability: Rugged cast iron frame and cylinder, rugged steel base, NEMA compliant motor housing

Superior pump efficiency: individually cast cylinders with deep radial fins for improved cooling and efficiency

Soft start: automatic start/stop regulation by pressure switch centrifugal unloader provides no-load start for maximum protection

Advanced safety features: standard low oil level switch to provide continuous compressor protection

Reliable performance: All Season Select synthetic lubricant improves efficiency; with 2,000 hours of service between changes, it lasts four times longer than a petroleum-based lubricant

Two-Year Warranty Available: Purchase the Select All-Season Lubricant Starter Kit and get all parts needed for start-up and first year of service, plus an extended pump warranty.

Ingersoll Rand Oil-Filled Screw Air Compressors incorporate the best of proven design and technology with new, enhanced functionality that delivers the highest levels of reliability, efficiency and performance. Ingersoll Rand not only provides world-class products and support, but gives you the peace of mind that comes from our commitment to supporting our customers in every aspect of our business.

The R-Series 4-11kW delivers optimum performance and ease of maintenance, all in a rugged, innovative package. Advanced innovations such as sealed PTFE hoses with O-ring face seals, a new generation compressor package and reduced component count continue our heritage of reliability in a compact design that fits in almost any application.

Improved Efficiency:An advanced compressor block design integrates key components to reduce creepage distances, improve reliability and improve VSD range.

Leak-Free Operation: V-Shield Technology provides a fully integrated leak-tight design with PTFE stainless steel braided oil hoses and o-ring mechanical seals.

Enhanced Productivity: The XeiSeries controller features an intuitive, high-resolution display with web-based communication and control.

Compact: Vertically arranged drive components reduce footprint and simplify maintenance

Improved Reliability: The aftercooling system greatly improves reliability and serviceability by providing cool, clean ambient air to key electrical components.

Offering the same reliability you expect, the well-equipped Ingersoll Rand UP6S series has raised the bar for functionality, performance and enhanced intelligence. We have developed a complete aerial solution that collects more information and puts more control in your hands.

Enhanced Reliability: With a durable TEFC Tri-Voltage (208-230/460V) motor, NEMA® 4 housing and Power Off Restart (PORO) capability, the UP6S series operates reliably and safely even in harsh environments.

Efficient Operation: The premium V-ribbed belt drive system uses a patented auto-tensioner to eliminate belt stretch and maximize air output.

Sealed Design: V-Shield Technology provides a fully integrated sealed design with stainless steel PTFE braided oil hoses and o-ring mechanical seals.

Smart Control: The Xe-70M programmable controller provides advanced control options through an intuitive user interface with large navigation buttons.

Improved Work Environment: Silent operation as low as 67 dBA allows installation closer to the point of use, reducing costs and providing a better and safer working environment 4 i vozmozhnosti perezapuska pri otklyuchenii pitaniya (PORO) seriya UP6S rabotayet nadezhno i bezopasno dazhe v surovykh

Ingersoll Rand is working to keep you ahead of the competition with next-generation R-Series air compressors that increase productivity, reduce operating costs and extend equipment life. And with Variable Speed Drive (VSD), the compressor automatically adjusts the compressed air output to maximize your performance, minimizing energy consumption at any load. Next generation R series air compressors. The intelligence you need to win.

Enhanced Efficiency: A modern, fully integrated compressor package delivers the efficiency and reliability you need.

Reduced energy consumption: IP55 enhanced efficiency motor delivers significant energy savings, while the built-in Variable Frequency Drive (VSD) further reduces energy consumption

Improved Serviceability: Easy access to all user-serviceable components, auto-tensioning V-belt and extended life, Ingersoll Rand premium coolant for increased uptime

Intelligent Remote Control: The Xe series controllers provide enhanced functionality with an intuitive user interface as well as remote access using any common current web browser.

Optional Total Air System (TAS): clean, dry air in a single enclosure that minimizes installation costs, reduces footprint and improves ISO air quality

Ingersoll Rand Nirvana variable speed screw compressors embody advances in alignment technology and reliability. Nirvana provides the ability to meet your compressed air needs while providing the lowest energy consumption and operating costs. And Nirvana's unique IntelliDrive has the ability to resize to different capacities to grow with your business.

Maximum Energy Efficiency: Nirvana's Variable Speed Drive (VSD) automatically adjusts compressed air output to maximize your performance, saving up to 35% on energy costs.

Increased Reliability: Fewer connections and smart integration eliminate leaks and pressure drops, improving reliability

Single point control: The Nirvana controller provides easy access to your compressed air system, offering excellent diagnostic capabilities to pinpoint service needs.

Scalable: The unique IntelliDrive system allows you to scale your compressor system to meet your business requirements with a simple firmware upgrade.

Improved Work Environment: Silent operation as low as 65 dBA allows installation closer to the point of use, reducing costs and providing a better and safer work environment

Optional Total Air System (TAS): clean, dry air in a single enclosure that minimizes installation costs, space, and delivers improved ISO air quality

Ingersoll Rand is working to keep you ahead of the competition with next-generation R-Series air compressors that increase productivity, reduce operating costs and extend equipment life. Next generation R series air compressors. The intelligence you need to win.

Improved Efficiency and Airflow: Airend features an optimized rotor profile that delivers up to 16% more efficiency and 21% more airflow capacity.

Intelligent Remote Control: The Xe Series controller provides advanced control options with an intuitive user interface and remote access using any common current web browser.

Scalable: The unique IntelliDrive system allows you to scale your compressor system to meet your business requirements with a simple firmware upgrade.

Reduced Downtime: Progressive Adaptive Control (PAC™) monitors key operating parameters and constantly adapts to prevent unexpected downtime.

Reduced energy consumption: Energy efficient NEMA Premium® motor provides significant energy savings and optional variable speed drive (VSD) further reduces energy requirements

Optional Total Air System (TAS): clean, dry air in a single enclosure that minimizes installation costs, space, and delivers improved ISO air quality

Ingersoll Rand is working to keep you ahead of the competition with next-generation R-Series air compressors that increase productivity, reduce operating costs and extend equipment life. Next generation R series air compressors. The intelligence you need to win.

Enhanced Efficiency: A modern, fully integrated compressor package delivers the efficiency and reliability you need.

Reduced Energy Consumption: The IP55 enhanced efficiency motor delivers significant energy savings, while the optional integrated Variable Speed Drive (VSD) further reduces power consumption.

Robust construction: Durable parts such as solid hoses, Vitron Victaulic pipe connections and an innovative separator ensure reliability throughout the life of your compressor.

Improved serviceability: Smart design elements such as easy access to user-serviceable components and premium coolant provide increased uptime

Intelligent Remote Control: The Xe series controllers provide enhanced functionality with an intuitive user interface as well as remote access using any common current web browser.

Optional Premium Package: Choose the IE version with the most efficient compressor unit for an additional energy saving of up to 6%.

Intelligent Uptime: Integrated with Helix™ Connected Platform, a state-of-the-art system that gives you insights and real-time data to keep your compressor running at peak performance and reducing the risk of downtime.

Ingersoll Rand R Series compressors offer the best of proven design and technology with advanced features to deliver the highest levels of reliability, efficiency and performance. And with Variable Speed Drive (VSD), the compressor automatically adjusts the compressed air output to maximize your performance, minimizing energy consumption at any load

Efficient design: proven compressor blocks, sequential cooling system and optional energy recovery system (ERS) significantly increase efficiency

Sealed Design: V-Shield Technology provides a fully integrated sealed design with stainless steel PTFE braided oil hoses and o-ring mechanical seals.

Intelligent Remote Control: The Xe Series controller provides advanced control options with an intuitive user interface and remote access using any common current web browser.

Reduced Downtime: Progressive Adaptive Control (PAC™) monitors key operating parameters and constantly adapts to prevent unexpected downtime.

Trouble-free operation: Features such as two-stage filtration, ease of maintenance and extended life of Ingersoll Rand premium coolant keep your operation running smoothly.

Optional Total Air System (TAS): clean, dry air in a single enclosure that minimizes installation costs, space, and delivers improved ISO air quality

Ingersoll Rand R Series compressors offer the best of proven design and technology with advanced features to deliver the highest levels of reliability, efficiency and performance.

Efficient design: proven compressor blocks, sequential cooling system and optional energy recovery system (ERS) significantly increase efficiency

Sealed Design: V-Shield Technology provides a fully integrated sealed design with stainless steel PTFE braided oil hoses and o-ring mechanical seals.

Intelligent Remote Control: The Xe Series controller provides advanced control options with an intuitive user interface and remote access using any common current web browser.

Reduced Downtime: Progressive Adaptive Control (PAC™) monitors key operating parameters and constantly adapts to prevent unexpected downtime.

Trouble-free operation: Features such as two-stage filtration, ease of maintenance and extended life of Ingersoll Rand premium coolant keep your operation running smoothly.

Ingersoll Rand is working to keep you ahead of the competition with next-generation R-Series air compressors that increase productivity, reduce operating costs and extend equipment life. Next generation R series air compressors. The intelligence you need to win.

Enhanced Efficiency: A state-of-the-art semi-integrated compressor package delivers the efficiency and reliability you need.

Reduced Energy Consumption: The IP55 enhanced efficiency motor delivers significant energy savings, while the optional integrated Variable Speed Drive (VSD) further reduces power consumption.

Improved serviceability: Smart design elements such as easy access to user-serviceable components and premium coolant reduce maintenance requirements and increase uptime.

Intelligent Remote Control: The Xe series controllers provide enhanced functionality with an intuitive user interface as well as remote access using any common current web browser.

Intelligent Uptime: Integrated with Helix™ Connected Platform, a state-of-the-art system that gives you insights and real-time data to keep your compressor running at peak performance and reducing the risk of downtime.

Ingersoll Rand is working to keep you ahead of the competition with next-generation R-Series air compressors that increase productivity, reduce operating costs and extend equipment life. Next generation R series air compressors. The intelligence you need to win.

Improved Efficiency and Airflow: Airend features an optimized rotor profile that delivers up to 18% efficiency gains and best-in-class airflow capacity.

Intelligent Remote Control: The Xe Series controller provides advanced control options with an intuitive user interface and remote access using any common current web browser.

Sealed Design: V-Shield Technology provides a fully integrated sealed design with stainless steel PTFE braided oil hoses and o-ring mechanical seals.

Reduced Downtime: Progressive Adaptive Control (PAC™) monitors key operating parameters and constantly adapts to prevent unexpected downtime.

Reduced energy consumption: Energy efficient NEMA Premium® motor delivers significant energy savings

Flexible Design Options: Air-cooled, water-cooled, and heavy-duty options (low and high ambient temperatures, outdoor operation) are available to best suit your work requirements.

Ingersoll Rand offers a wide range of oil-free compressors that can be upgraded to meet your industry and application requirements.

Ingersoll Rand offers a wide range of solutions for compressing air and gas using centrifugal compressors.

It includes MSG® Centac® and MSG® TURBO-AIR® plant air compressors as well as MSG® process air and process gas compressors. In addition to equipment, Ingersoll Rand also offers a wide range of services for compressed air systems, including installation, system upgrades, compressed air system assessment and audit, and scheduled or emergency maintenance.

We have expanded our centrifugal compressor product line by acquiring the former centrifugal compressor business of Cameron International. With this acquisition, we have expanded our portfolio to include the TURBO-AIR® and MSG® centrifugal air compressor product lines, in addition to our Centac brand. The addition of TURBO-AIR and MSG centrifugal compressors expands our market coverage to higher pressure, higher flow and process gas compression applications.

Designed for the PET Industry Ingersoll Rand addresses the unique challenges of blowing PET bottles with advanced air compressor technology tailored to your individual production requirements.

Ingersoll Rand four-stage centrifugal and four-stage reciprocating compressors deliver the critical performance you need to maximize productivity. Ingersoll Rand PET compressors provide:

Specifically designed for demanding PBM applications, Ingersoll Rand MSG® Centac® centrifugal compressors require very low maintenance as they have few moving parts and are not subject to wear. Their compact, innovative design provides an exceptional level of reliability to keep you up and running at peak performance.

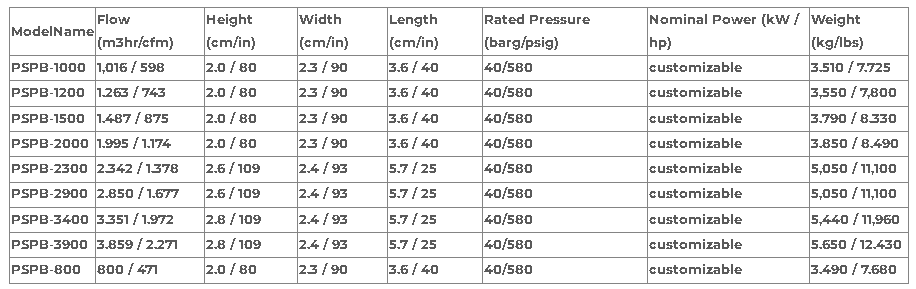

The production of large PET bottles often requires large amounts of high and low pressure air. The primary boost system provides the flexibility to meet changing requirements. The Ingersoll Rand Primary Booster System is a modular approach in which the primary compressor is complemented by a booster. The primary compressor can be an oil-free rotary or centrifugal compressor to suit your needs, while a 2-stage oil-free piston compressor serves as a booster to easily adjust system performance as demand changes.